| Request Quote |

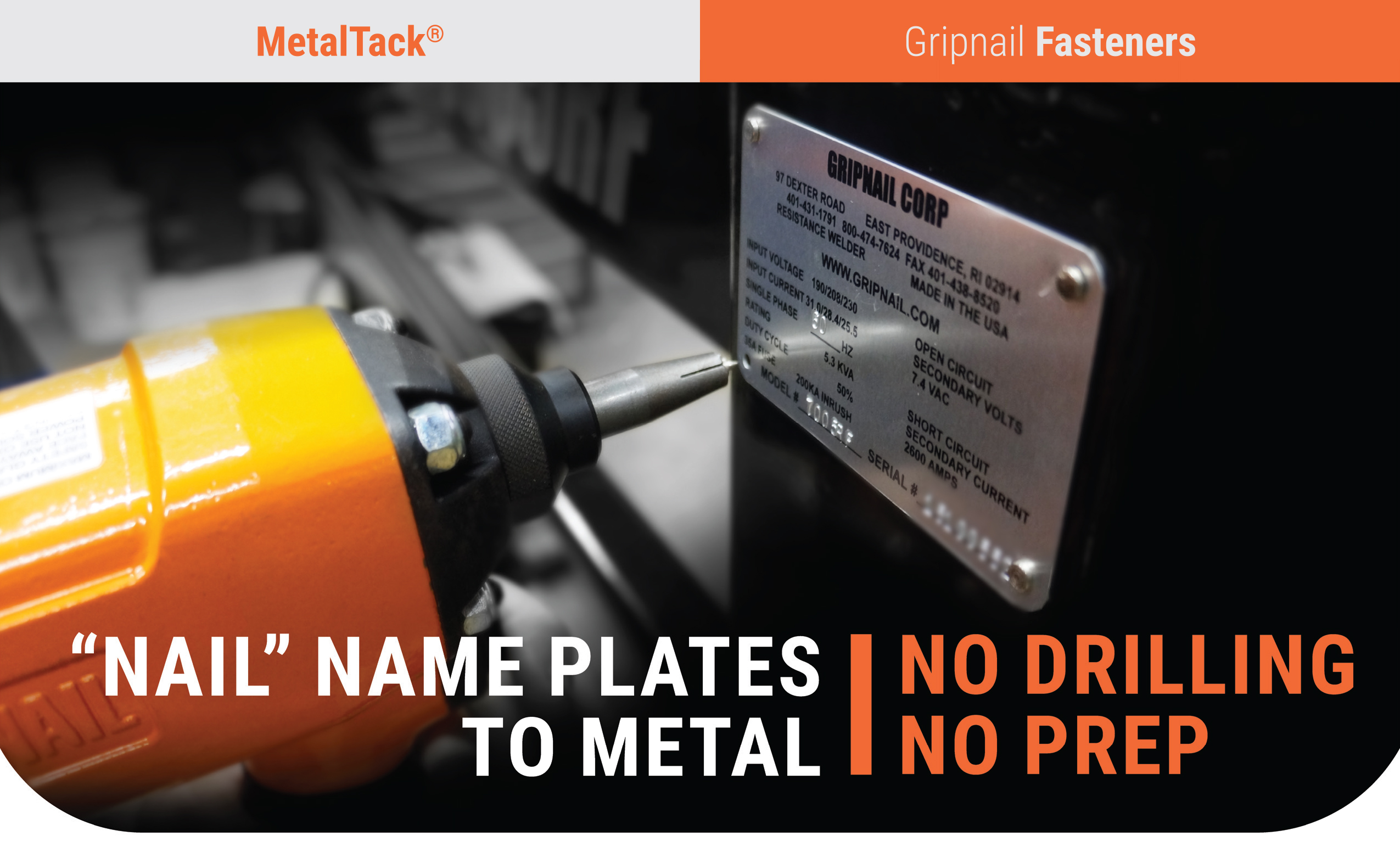

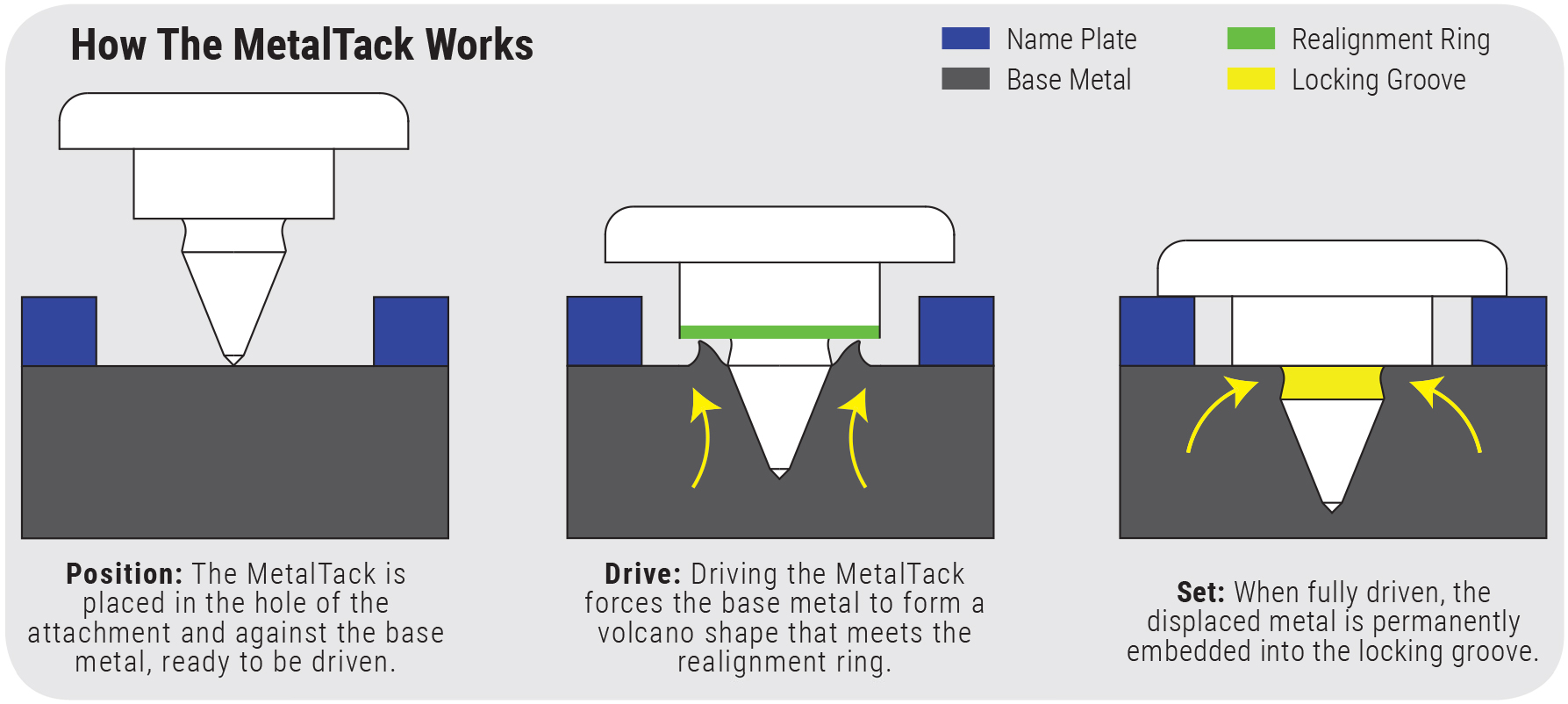

A MetalTack Fastens lightweight parts to solid metal products such as pumps, valves and machinery. It is impacted directly into the base metal and forms a permanent mechanical connection which will hold up to 250 pounds. There is no need for drilling or other surface preparation and MetalTack is perfect for attaching name plates, barcode tags, and cable tie mounts.

A MetalTack Fastens lightweight parts to solid metal products such as pumps, valves and machinery. It is impacted directly into the base metal and forms a permanent mechanical connection which will hold up to 250 pounds. There is no need for drilling or other surface preparation and MetalTack is perfect for attaching name plates, barcode tags, and cable tie mounts.

![]()

Adhesives have a “shelf life” which makes using them a less than permanent solution; while drilling requires perfect alignment between base metal and attachment. Furthermore, drilling holes is laborious and may cause damage. Metal drill chips are difficult to clean and may risk expensive machinery. Using a MetalTack prevents any foreign object debris from entering any work environment of moving component.

Adhesives have a “shelf life” which makes using them a less than permanent solution; while drilling requires perfect alignment between base metal and attachment. Furthermore, drilling holes is laborious and may cause damage. Metal drill chips are difficult to clean and may risk expensive machinery. Using a MetalTack prevents any foreign object debris from entering any work environment of moving component.

Is manufactured from carbon steel, and are zinc plated. It will pass a minimum 120-hour salt spray test in accordance with ASTM B117. It may be driven into base metals as hard as HRB90.

Is manufactured from hardened stainless steel and are not plated. The fastener has a small amount of carbon and form slight blush rust after exposure to corrosive environments. It can penetrate base metals as hard as HRB90 as well as many grades of stainless steel.

Is manufactured from a special steel alloy that allows them to become harder and tougher than a standard fastener. A Tool Steel MetalTack can penetrate materials as hard as HRB100. The fastener is also zinc chromate plated for the same corrosion resistance as standard tacks.

If the exact fastener for your application does not appear on the Sizing Chart, call us to see if we might be able to make it for you. Many custom sized MetalTack fasteners have been produced with a variety of grip lengths, shank diameters and point lengths for specific applications. Special plating such as nickel, are also available to meet particular corrosion or cosmetic requirements.

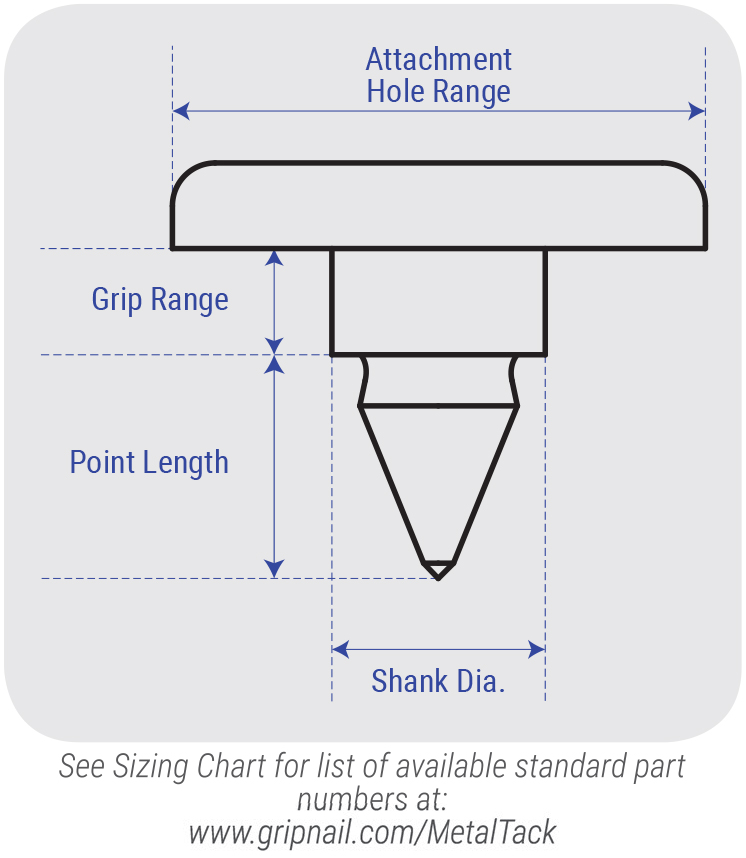

A Standard MetalTack is available in three materials, three head diameters, two point lengths and graduated grip range from 0.010" (0.254mm) to 0.125" (3.175mm). Use the Sizing Chart and the following guidelines to help you select the best MetalTack for your application.

A Standard MetalTack is available in three materials, three head diameters, two point lengths and graduated grip range from 0.010" (0.254mm) to 0.125" (3.175mm). Use the Sizing Chart and the following guidelines to help you select the best MetalTack for your application.

MetalTack selection is based upon two factors. The material that is going to fastened (attachment) and the material that the attachment is going to be fastened to (base metal)

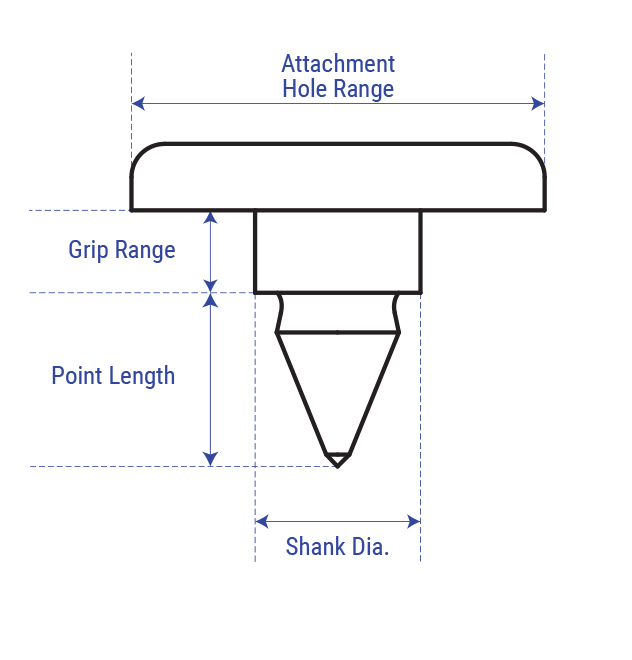

The part that you are fastening is referred to as the attachment. Typical attachments are name plates, cable tie mounts and small components. The attachment will need to have a prefabricated hole in it and will be secured between the head of the MetalTack and the base metal. Consult the Sizing Chart for a range of attachment hole sizes. Larger holes provide an easier "target" for the operator.

A MetalTack will fasten to most malleable metals including steel, stainless steel, brass, bronze and aluminum. A MetalTack will also fasten to many grades of cast iron and die cast material. It is best to select a Tool Steel tack for cast iron class 35 or higher, and a large point fastener is recommended for softer material such as zinc die-castings and aluminum.

Grip Range

Grip RangeYour attachment (name plate, cable tie mounts, etc.) must fit between the head of the MetalTack and the surface of the base metal. The grip range may penetrate the base metal up to 0.010" (0.254mm).

Two size of point lengths are offered 0.062" (1.574mm) and 0.106" (2.6924mm). Use the larger point for increase withdrawal resistance and the small point in thin metals.

The hold in your attachment must be greater than the shank diameter and less than the head diameter.

Grip Range

Grip Range

Your attachment (name plate, cable tie mount, etc.) must fit between the head of the MetalTack and the surface of the base metal. The grip range may penetrate the base metal up to 0.010" (0.254mm).

Point Length

Two Sizes of point lengths are offered:

0.062" (1.574mm)

0.106" (2.692mm)

Use the larger point for increase withdrawal resistance and the smaller point in thin metals.

Attachment Hole Range

The hole in your attachment must be greater than the shank diameter and less than the head diameter.

| Zoom In (Chart) | Zoom In (Diagram) |